| Availability: | |

|---|---|

| Quantity: | |

HR-12KW-4AC

HIPOWER

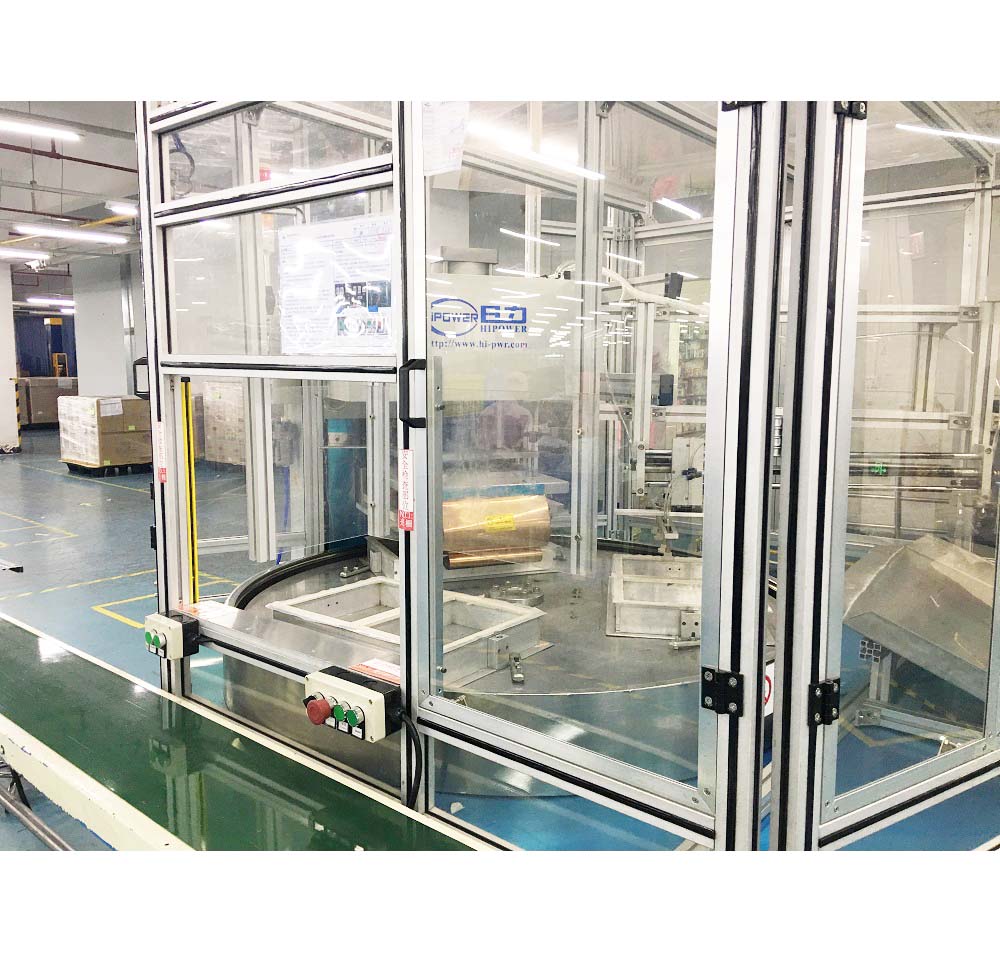

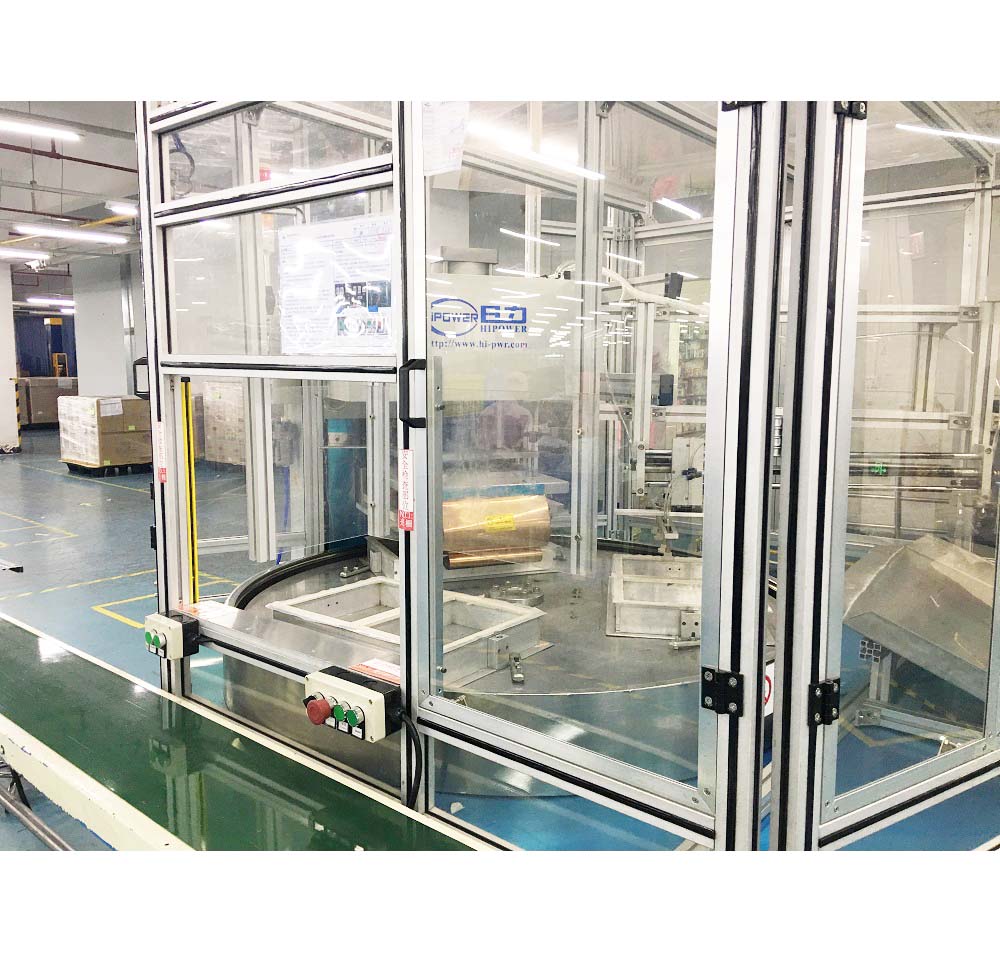

Welding and Cutting for blister packaging,for welding and cutting blister of PVC,PET,APET,PETG,GAG and other eco-friendly material;it is turn table, HF welding and cutting machine.

Automatic Printed Film and Blister Packing Machine with HF Welding Cutting Design

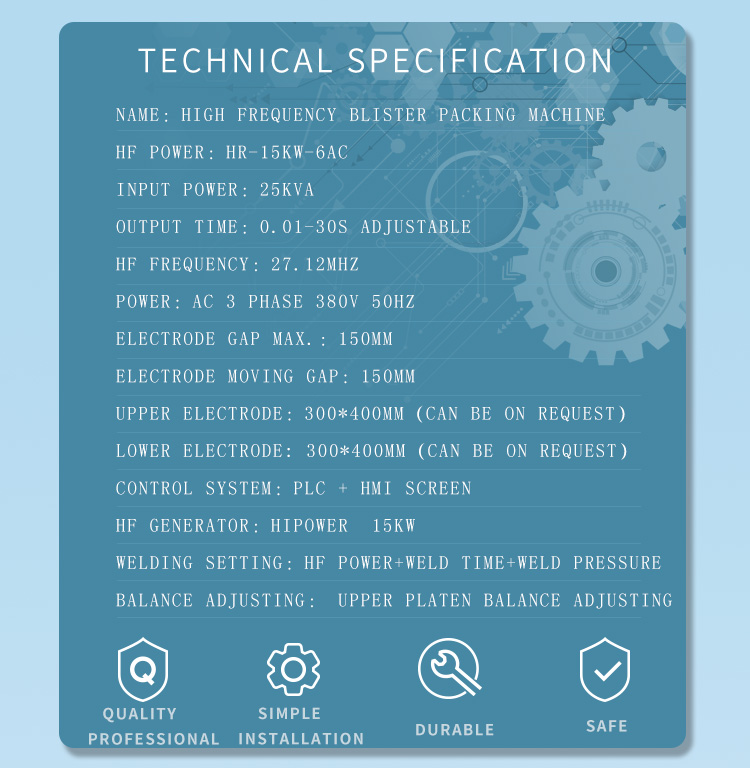

Model | HR-8KW-4AC | HR-10KW-4AC | HR-12KW-4AC | HR-15KW-4AC |

HF Power | 8KW | 10KW | 12KW | 15KW |

HF Frequency | 27.12MHZ | |||

Voltage | AC 380V 3Phases 50HZ / Customer request | |||

Pneumatic Pressure | 0.1 - 0.8Mpa | |||

Input Power: | 15KVA | 18KVA | 20KVA | 25KVA |

Max. Pressure: | 20Tons Pneumatic | |||

Max. Electrodes Gap : | 150MM | |||

Electrode Gap: | 175MM | |||

Upper Electrode: | 300*400mm | 300*400mm | 400*500mm | |

Lower Work Platen: | 300*400mm | 300*400mm | 400*500mm | |

Output Time | 0.01 - 30S Adjustable | |||

Control Method | Control Panel Type( PLC+HMI Touch screen on extra cost) | |||

HF Generator | HIPOWER 8KW | HIPOWER 10KW | HIPOWER 12KW | HIPOWER 15KW |

Parameter Setting | HF Power+Time Adjusting+Pressure Adjusting | |||

Welding Depth Setting | HF Power+Time Adjusting+Pressure Adjusting | |||

Balance Setting | Upper Electrode Balance + Balance Screws Adjusting | |||

Optional Function | Auto Tuning System on Extra cost | |||

Standard | CE Certificate | |||

Packing Information | L2150*W1050*H1950 mm; G.W.: 580KGS; | |||

1. Anti-flash system, to protect the tooling / mould; C-Frame welded steel structure with integrated HF generator

2. Equipped with special high precision rotary indexing gear controlled by frequency inverter.

3. Automated HF weld cycles with adjustable rotating speed

4. With the use of touch screen HMI and programmable PLC operator can easily input parameters set.

5. Heated Upper platen with thermostat, for helping HF sealing process

6. Close off HF welding function, the machine can be use as Standard Heat Welder

7. Universal usage for PVC, PET-G,A-PET,GAG, PU, PET, PLA films

8. European-model square high frequency vibration box, more reliable and stable in output

9. CE rated machine; factory verified by SGS and BV;

10. Customer's site installation, training & maintenance available.

11. Online service by Email, Fax, Video Online- allowing remote live video servicing of basic setup and repairs through the use of face-to-face online video.

12. High frequency welding press pneumatically operated.

Welding and Cutting for blister packaging,for welding and cutting blister of PVC,PET,APET,PETG,GAG and other eco-friendly material; It is turn table, HF welding and cutting machine.

5、Work-Flow of equipment

Station 1: ——Feed Blister clam-shell and products into lower mold by hand

Station 2: —— Printed soft PVC film pulling, cutting and positioning

Station 3: ——H.F. Welding blister & pvc film together

Station 4: ——Robot unit pick-up finished products

Station 5:—— Robot hold products to hook holes die cutting station to cut holes

Station 6:——Robot transfer products to die cutting machine

Station 7:——Die cutting machine cut outside waste of products

Station 8:——Robots pick up finished products and wastes to conveyor line.

Station 9:——Operators separate products from waste by picking up from conveyor line

Welding and Cutting for blister packaging,for welding and cutting blister of PVC,PET,APET,PETG,GAG and other eco-friendly material;it is turn table, HF welding and cutting machine.

Automatic Printed Film and Blister Packing Machine with HF Welding Cutting Design

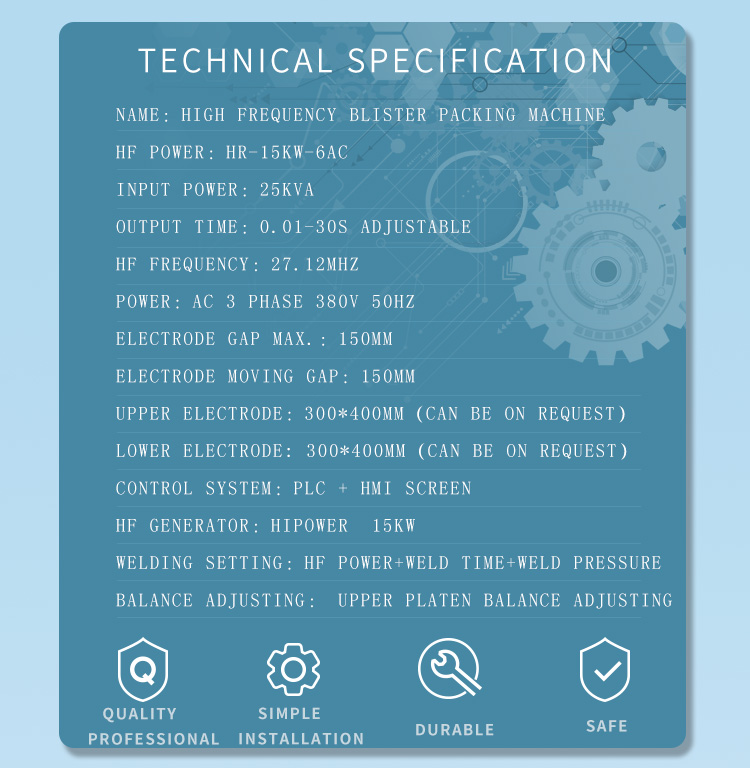

Model | HR-8KW-4AC | HR-10KW-4AC | HR-12KW-4AC | HR-15KW-4AC |

HF Power | 8KW | 10KW | 12KW | 15KW |

HF Frequency | 27.12MHZ | |||

Voltage | AC 380V 3Phases 50HZ / Customer request | |||

Pneumatic Pressure | 0.1 - 0.8Mpa | |||

Input Power: | 15KVA | 18KVA | 20KVA | 25KVA |

Max. Pressure: | 20Tons Pneumatic | |||

Max. Electrodes Gap : | 150MM | |||

Electrode Gap: | 175MM | |||

Upper Electrode: | 300*400mm | 300*400mm | 400*500mm | |

Lower Work Platen: | 300*400mm | 300*400mm | 400*500mm | |

Output Time | 0.01 - 30S Adjustable | |||

Control Method | Control Panel Type( PLC+HMI Touch screen on extra cost) | |||

HF Generator | HIPOWER 8KW | HIPOWER 10KW | HIPOWER 12KW | HIPOWER 15KW |

Parameter Setting | HF Power+Time Adjusting+Pressure Adjusting | |||

Welding Depth Setting | HF Power+Time Adjusting+Pressure Adjusting | |||

Balance Setting | Upper Electrode Balance + Balance Screws Adjusting | |||

Optional Function | Auto Tuning System on Extra cost | |||

Standard | CE Certificate | |||

Packing Information | L2150*W1050*H1950 mm; G.W.: 580KGS; | |||

1. Anti-flash system, to protect the tooling / mould; C-Frame welded steel structure with integrated HF generator

2. Equipped with special high precision rotary indexing gear controlled by frequency inverter.

3. Automated HF weld cycles with adjustable rotating speed

4. With the use of touch screen HMI and programmable PLC operator can easily input parameters set.

5. Heated Upper platen with thermostat, for helping HF sealing process

6. Close off HF welding function, the machine can be use as Standard Heat Welder

7. Universal usage for PVC, PET-G,A-PET,GAG, PU, PET, PLA films

8. European-model square high frequency vibration box, more reliable and stable in output

9. CE rated machine; factory verified by SGS and BV;

10. Customer's site installation, training & maintenance available.

11. Online service by Email, Fax, Video Online- allowing remote live video servicing of basic setup and repairs through the use of face-to-face online video.

12. High frequency welding press pneumatically operated.

Welding and Cutting for blister packaging,for welding and cutting blister of PVC,PET,APET,PETG,GAG and other eco-friendly material; It is turn table, HF welding and cutting machine.

5、Work-Flow of equipment

Station 1: ——Feed Blister clam-shell and products into lower mold by hand

Station 2: —— Printed soft PVC film pulling, cutting and positioning

Station 3: ——H.F. Welding blister & pvc film together

Station 4: ——Robot unit pick-up finished products

Station 5:—— Robot hold products to hook holes die cutting station to cut holes

Station 6:——Robot transfer products to die cutting machine

Station 7:——Die cutting machine cut outside waste of products

Station 8:——Robots pick up finished products and wastes to conveyor line.

Station 9:——Operators separate products from waste by picking up from conveyor line

Apply for APET, PETG, GAG environmentally friendly materials double side blister packaging and sealing, blister

+ paper card packaging , toothbrush sealed packaging, EVA leather cloth, leather, OPP, PU material welding and fusing. Mainly

used for a variety of plastic products forming,and different shapes blister automatic trimming. For PVC double blister sealing,

plastic and paper card sealing, environmental APET film equivalent, soft line indentation punching forming, environmental APET

double blister sealing and trimming simultaneously, special materials sealing.

PET Toothbrush Blister Sealing Welding Machine

Apply for APET, PETG, GAG environmentally friendly materials double side blister packaging and sealing, blister

+ paper card packaging , toothbrush sealed packaging, EVA leather cloth, leather, OPP, PU material welding and fusing. Mainly

used for a variety of plastic products forming,and different shapes blister automatic trimming. For PVC double blister sealing,

plastic and paper card sealing, environmental APET film equivalent, soft line indentation punching forming, environmental APET

double blister sealing and trimming simultaneously, special materials sealing.

PET Toothbrush Blister Sealing Welding Machine