| Availability: | |

|---|---|

| Quantity: | |

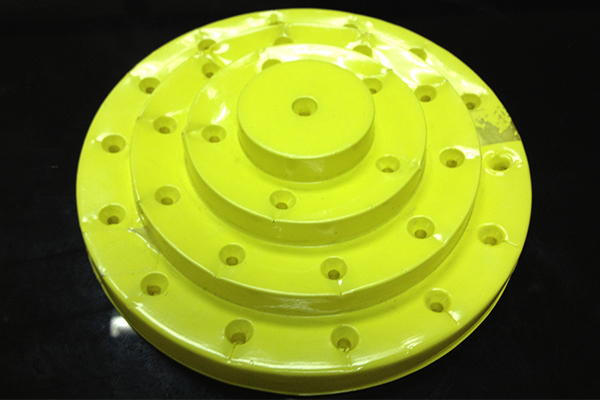

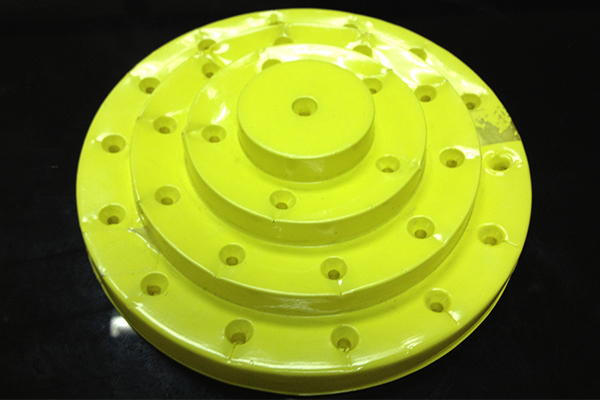

HY-450

HIPOWER

This machine can use almost all kinds of plastic material, like PP, PVC, PET, OPP, PE and so on, can make lids with diameter.

This machine can use almost all kinds of plastic material, like PP, PVC, PET, OPP, PE and so on,

you can make lids with diameter 30-200mm by changing mould.

Model: | HY-450 |

Power Input: | 3P 380V 50HZ / Custom |

Max. Forming Depth: | 35mm (Speical request on extra cost) |

Raw Material Width: | <430mm |

Cylinder diameter: | 80mm-200mm |

Cylinder Length: | 50mm-300mm (before curling) |

Film Thickness: | 0.17mm-0.5mm |

Control System: | PLC+HMI touch screen |

Power | 4.5KW |

Material film applied | PVC, PET-G and other ultrasonic weldable plastic films |

Production Speed: | 500 to 900pcs/ hour ( depend on diameter&height) |

Water Consumption: | 0.3m3/h |

Standard: | CE Certificate |

1. Compact Configuration, Easy Manipulation.

2. Sleeplessly Variable Frequency Speed Regulating, PC Circuit Control Panel.

3. Adjustable travel, convenient for replacing mould.

4. Can design any mould and feeder according to customers advice

5. PLC Touch screen control

6. Optional function: inside flying cutter

To produce plastic lid, plastic covers of cylinder box. It can also applied for blister forming application

1. Cylinder Box from PVC, PET

2. Clear or Printing Jar Box

3. Round, Oval, Conical All in one line

4. Wall thickness 0.14mm to 0.8mm

5. Diameter: 30mm to 200mm

6. Height: 50mm to 300mm

Do you have the CE certificatre of the Automatic Plastic Lid Cover Forming Machine?

Is it easy to be imported from China?

Since 2000, Hipower concentrates on highest quality, on-time delivery, professional technology

support, customer-oriented service and competitive price.

1. Customer's site installation, training & maintenance available

2. (Time zone difference) 1-12 hours Online service by Email, Fax, Video Online for basic setup and repairs

3. Service of 12 months warranty for machine, life-long tech. support

4. Examining mold drawings on your behalf to confirm optimum structure size meeting high frequency process;

5. Providing assistance in manufacturing and modifying tools;

This machine can use almost all kinds of plastic material, like PP, PVC, PET, OPP, PE and so on, can make lids with diameter.

This machine can use almost all kinds of plastic material, like PP, PVC, PET, OPP, PE and so on,

you can make lids with diameter 30-200mm by changing mould.

Model: | HY-450 |

Power Input: | 3P 380V 50HZ / Custom |

Max. Forming Depth: | 35mm (Speical request on extra cost) |

Raw Material Width: | <430mm |

Cylinder diameter: | 80mm-200mm |

Cylinder Length: | 50mm-300mm (before curling) |

Film Thickness: | 0.17mm-0.5mm |

Control System: | PLC+HMI touch screen |

Power | 4.5KW |

Material film applied | PVC, PET-G and other ultrasonic weldable plastic films |

Production Speed: | 500 to 900pcs/ hour ( depend on diameter&height) |

Water Consumption: | 0.3m3/h |

Standard: | CE Certificate |

1. Compact Configuration, Easy Manipulation.

2. Sleeplessly Variable Frequency Speed Regulating, PC Circuit Control Panel.

3. Adjustable travel, convenient for replacing mould.

4. Can design any mould and feeder according to customers advice

5. PLC Touch screen control

6. Optional function: inside flying cutter

To produce plastic lid, plastic covers of cylinder box. It can also applied for blister forming application

1. Cylinder Box from PVC, PET

2. Clear or Printing Jar Box

3. Round, Oval, Conical All in one line

4. Wall thickness 0.14mm to 0.8mm

5. Diameter: 30mm to 200mm

6. Height: 50mm to 300mm

Do you have the CE certificatre of the Automatic Plastic Lid Cover Forming Machine?

Is it easy to be imported from China?

Since 2000, Hipower concentrates on highest quality, on-time delivery, professional technology

support, customer-oriented service and competitive price.

1. Customer's site installation, training & maintenance available

2. (Time zone difference) 1-12 hours Online service by Email, Fax, Video Online for basic setup and repairs

3. Service of 12 months warranty for machine, life-long tech. support

4. Examining mold drawings on your behalf to confirm optimum structure size meeting high frequency process;

5. Providing assistance in manufacturing and modifying tools;