| Availability: | |

|---|---|

| Quantity: | |

HR-10KW-4AC

HIPOWER

Product Introduction:

Not only for welding PVC,PET,A-PET,PET-G,GAG blister, but also for cutting waste of PVC,PET,A-PET,PET-G,GAG blister and cardboard, auto robot for picking up finished products.

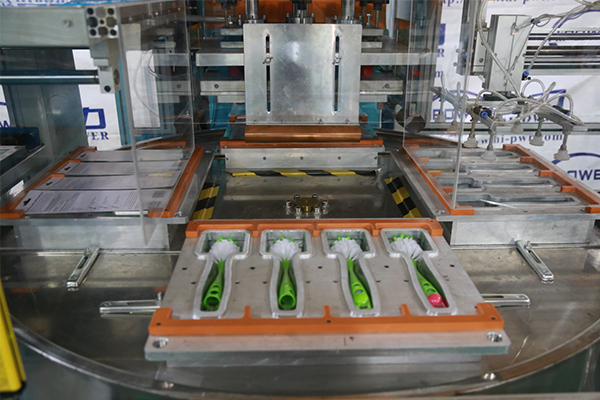

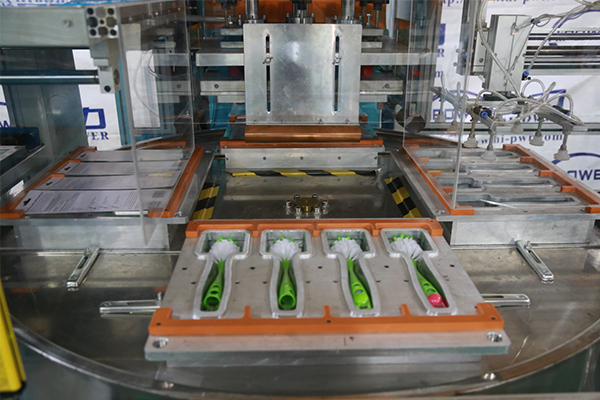

Product Photos

Welded Samples

1. European Designed Generator: Strong, Stable and low HF radiation Level

2. Three sides HF grounding design, less HF radiation around the machine

3. Auto turn-table, with 4 working station, working cycle time: 9s to 15s

4. With Automatic robot to pick up finished products.

5. Original New air cooling for electron tube

6. Special HF Radiation treatment

7. CE certificate, be able to exported to many countries

Auto 4 rotate working stations, with robot pick-up finished products, HF welding and cutting function in one machine, 5557 Arc-suppressor included, CE rated machine

Apply for APET, PETG, GAG environmentally friendly materials double side blister packaging and sealing, blister

+ paper card packaging , toothbrush sealed packaging, EVA leather cloth, leather, OPP, PU material welding and fusing. Mainly

used for a variety of plastic products forming,and different shapes blister automatic trimming. For PVC double blister sealing,

plastic and paper card sealing, environmental APET film equivalent, soft line indentation punching forming, environmental APET

double blister sealing and trimming simultaneously, special materials sealing.

Model | HR-8KW-4AC | HR-10KW-4AC | HR-12KW-4AC | HR-15KW-4AC |

HF Power | 8KW | 10KW | 12KW | 15KW |

HF Frequency | 27.12MHZ | |||

Voltage | AC 380V 3Phases 50HZ / Customer request | |||

Pneumatic Pressure | 0.1 - 0.8Mpa | |||

Input Power: | 15KVA | 18KVA | 20KVA | 25KVA |

Max. Pressure: | 20Tons Pneumatic | |||

Max. Electrodes Gap : | 150MM | |||

Electrode Gap: | 175MM | |||

Upper Electrode: | 300*400mm | 300*400mm | 400*500mm | |

Lower Work Platen: | 300*400mm | 300*400mm | 400*500mm | |

Output Time | 0.01 - 30S Adjustable | |||

Control Method | Control Panel Type( PLC+HMI Touch screen on extra cost) | |||

HF Generator | HIPOWER 8KW | HIPOWER 10KW | HIPOWER 12KW | HIPOWER 15KW |

Parameter Setting | HF Power+Time Adjusting+Pressure Adjusting | |||

Welding Depth Setting | HF Power+Time Adjusting+Pressure Adjusting | |||

Balance Setting | Upper Electrode Balance + Balance Screws Adjusting | |||

Optional Function | Auto Tuning System on Extra cost | |||

Standard | CE Certificate | |||

Packing Information | L2150*W1050*H1950 mm; G.W.: 580KGS; | |||

Our machine is with CE certificate for different applications.

This high frequency blister packaging machine is researched and developed by Shenzhen Hipower Ltd itself.The procedure of this machine following:1. To seal blister of PVC, PET, PET-G, PET-GAG, A-PET

Product Introduction:

Not only for welding PVC,PET,A-PET,PET-G,GAG blister, but also for cutting waste of PVC,PET,A-PET,PET-G,GAG blister and cardboard, auto robot for picking up finished products.

Product Photos

Welded Samples

1. European Designed Generator: Strong, Stable and low HF radiation Level

2. Three sides HF grounding design, less HF radiation around the machine

3. Auto turn-table, with 4 working station, working cycle time: 9s to 15s

4. With Automatic robot to pick up finished products.

5. Original New air cooling for electron tube

6. Special HF Radiation treatment

7. CE certificate, be able to exported to many countries

Auto 4 rotate working stations, with robot pick-up finished products, HF welding and cutting function in one machine, 5557 Arc-suppressor included, CE rated machine

Apply for APET, PETG, GAG environmentally friendly materials double side blister packaging and sealing, blister

+ paper card packaging , toothbrush sealed packaging, EVA leather cloth, leather, OPP, PU material welding and fusing. Mainly

used for a variety of plastic products forming,and different shapes blister automatic trimming. For PVC double blister sealing,

plastic and paper card sealing, environmental APET film equivalent, soft line indentation punching forming, environmental APET

double blister sealing and trimming simultaneously, special materials sealing.

Model | HR-8KW-4AC | HR-10KW-4AC | HR-12KW-4AC | HR-15KW-4AC |

HF Power | 8KW | 10KW | 12KW | 15KW |

HF Frequency | 27.12MHZ | |||

Voltage | AC 380V 3Phases 50HZ / Customer request | |||

Pneumatic Pressure | 0.1 - 0.8Mpa | |||

Input Power: | 15KVA | 18KVA | 20KVA | 25KVA |

Max. Pressure: | 20Tons Pneumatic | |||

Max. Electrodes Gap : | 150MM | |||

Electrode Gap: | 175MM | |||

Upper Electrode: | 300*400mm | 300*400mm | 400*500mm | |

Lower Work Platen: | 300*400mm | 300*400mm | 400*500mm | |

Output Time | 0.01 - 30S Adjustable | |||

Control Method | Control Panel Type( PLC+HMI Touch screen on extra cost) | |||

HF Generator | HIPOWER 8KW | HIPOWER 10KW | HIPOWER 12KW | HIPOWER 15KW |

Parameter Setting | HF Power+Time Adjusting+Pressure Adjusting | |||

Welding Depth Setting | HF Power+Time Adjusting+Pressure Adjusting | |||

Balance Setting | Upper Electrode Balance + Balance Screws Adjusting | |||

Optional Function | Auto Tuning System on Extra cost | |||

Standard | CE Certificate | |||

Packing Information | L2150*W1050*H1950 mm; G.W.: 580KGS; | |||

Our machine is with CE certificate for different applications.

This high frequency blister packaging machine is researched and developed by Shenzhen Hipower Ltd itself.The procedure of this machine following:1. To seal blister of PVC, PET, PET-G, PET-GAG, A-PET

PVC Toothbrush Blister Packaging Welding Machine

This high frequency blister packaging machine is researched and developed by Shenzhen Hipower Ltd itself.

The procedure of this machine following:1. To seal blister of PVC, PET, PET-G, PET-GAG, A-PET

PVC Toothbrush Blister Packaging Welding Machine

This high frequency blister packaging machine is researched and developed by Shenzhen Hipower Ltd itself.

The procedure of this machine following:1. To seal blister of PVC, PET, PET-G, PET-GAG, A-PET