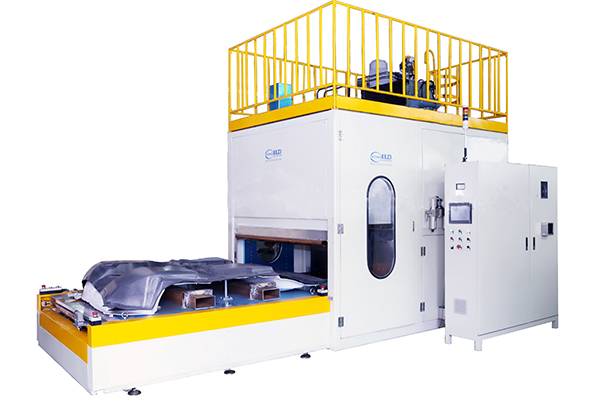

HR-15KW-2QT

HIPOWER

Product Introduction:

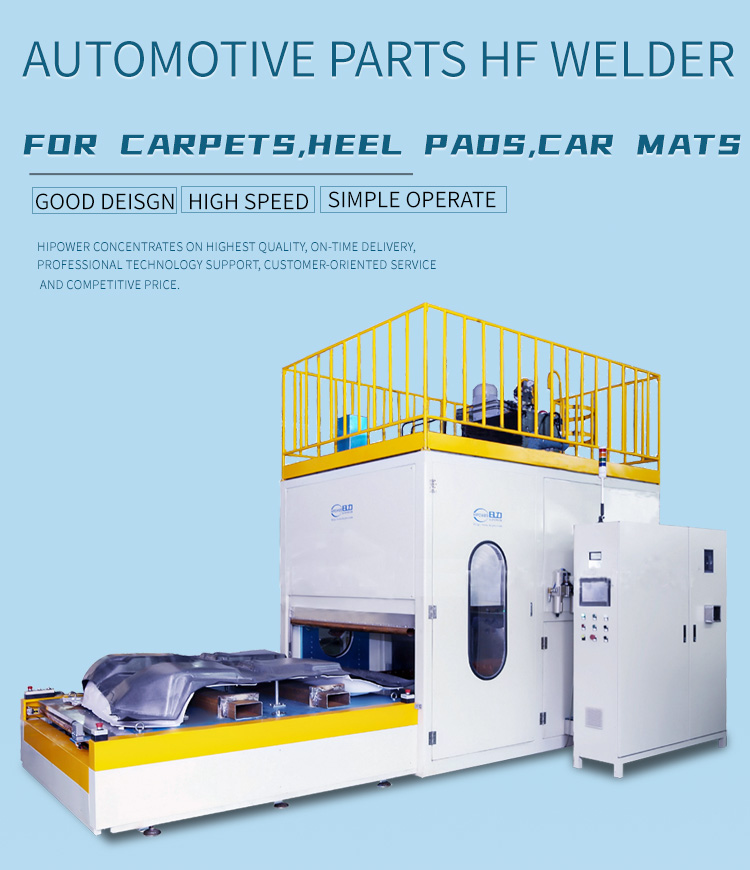

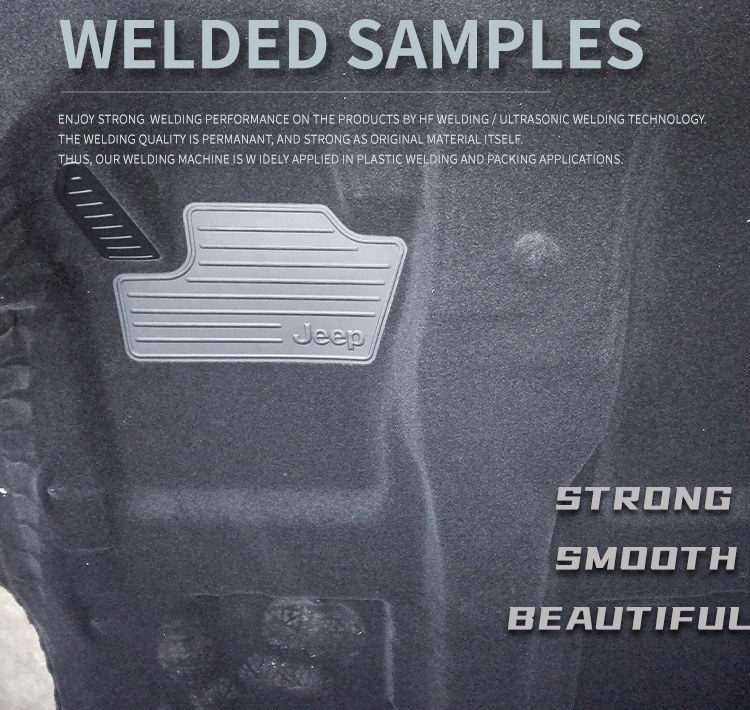

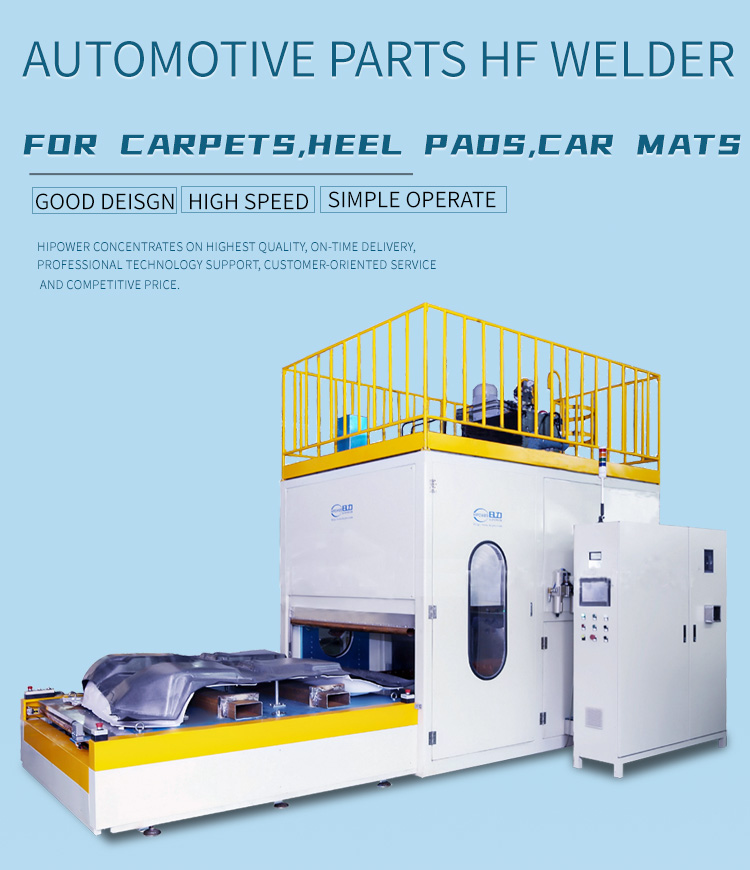

High Frequenc Welding Machine for Automobile Carpet

High Frequency Welding Machine for Automobile carpet which is suitable for PVC heelmat and automobile carpet .

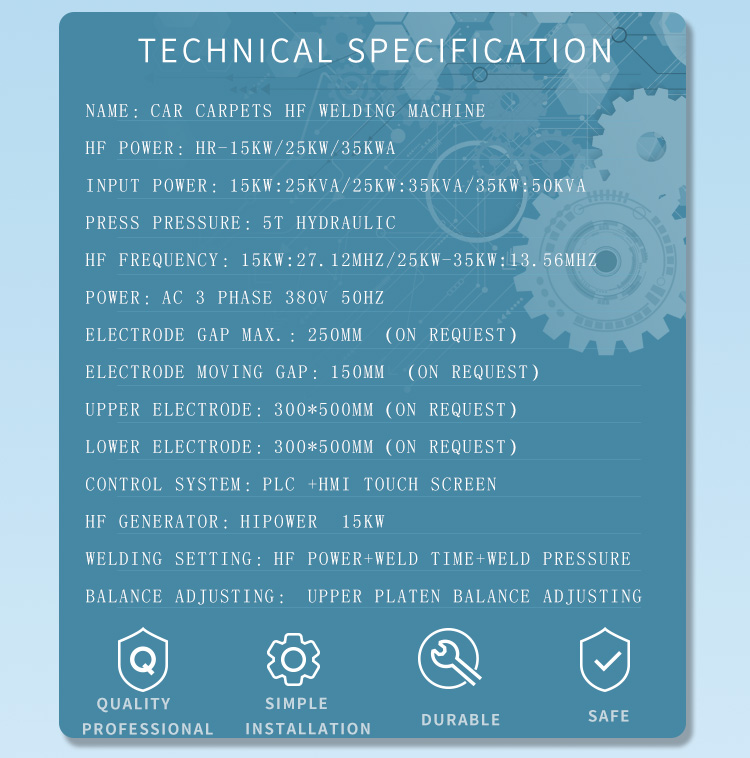

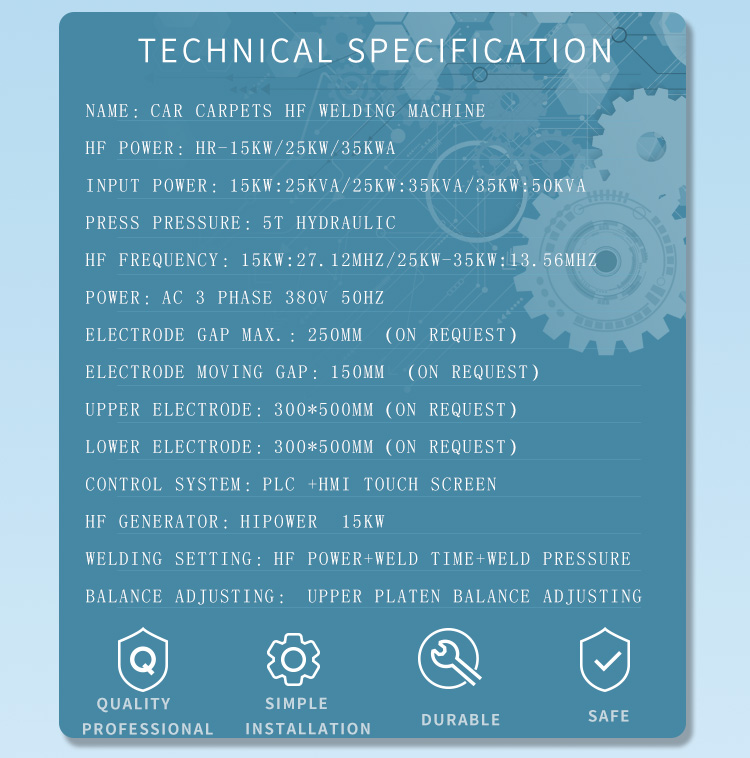

Model | HR-15KW-2QT | HR-25KW-2QT |

HF Power | 15KW | 25KW |

HF Frequency | 27.12MHZ | 13.56MHZ |

Input Power: | 18KVA | 25KVA |

HF Generator | HIPOWER 15KW | HIPOWER 25KW |

Voltage | AC 380V 3Phases 50HZ / Customer request | |

Pneumatic Pressure | 0.1 - 0.8Mpa | |

Max. Pressure: | 5T Hydraulic Pressure | |

Max. Electrodes Gap : | 250mm / On Request | |

Control Method | PLC+HMI Touch screen | |

Upper Electrode: | 400*500mm or up to product size | |

Lower Work Platen: | 400*500mm or up to product size | |

Output Time | 0.01 - 30S Adjustable | |

Parameter Setting | HF Power+Time Adjusting+Pressure Adjusting | |

Welding Depth Setting | HF Power+Time Adjusting+Pressure Adjusting | |

Balance Setting | Upper Electrode Balance + Balance Screws Adjusting | |

Optional Function | Auto Tuning System | |

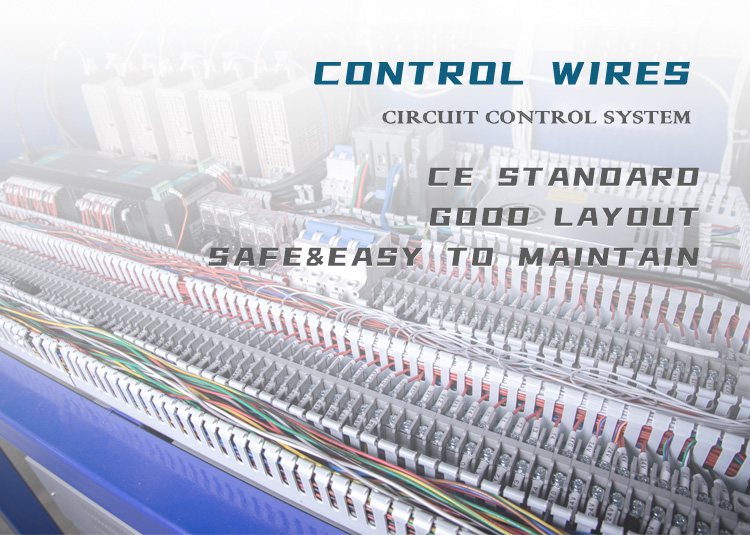

Standard | CE Certificate | |

3. Machine Features:

Auto Tuning System of HF welding power

Mold auto identification function.

Parameter Settings auto save

Various Welding Direction

European Parts Inside

Welding pressure: 5T hydraulic

System Auto diagnosis

Qualified RF Radiation Level

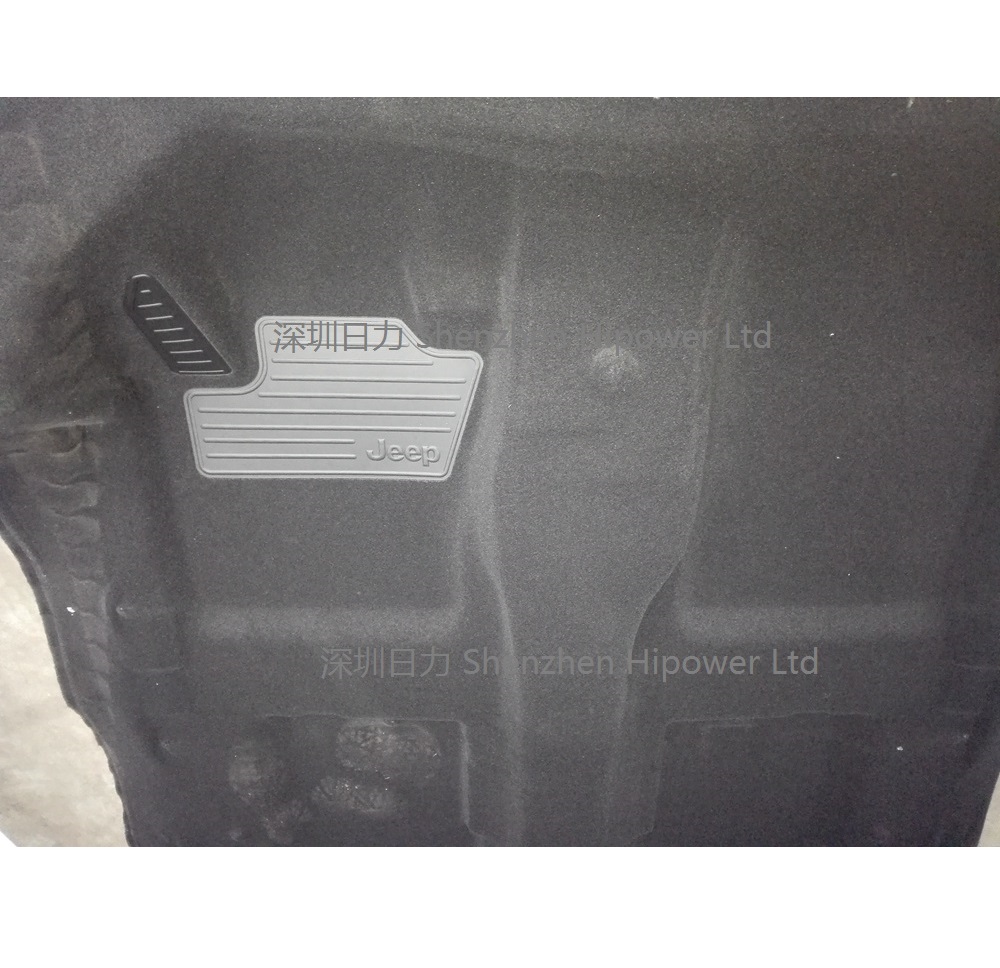

4. Application:

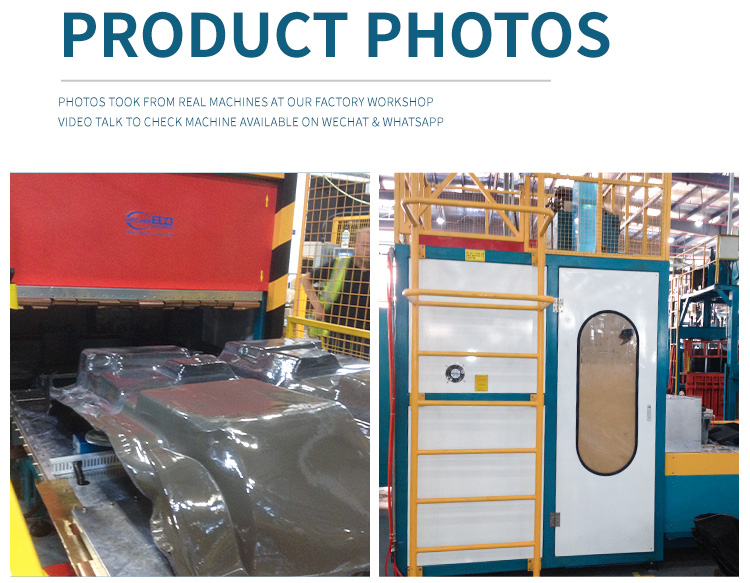

Automatic Car Carpet Welding Machine is specially designed for producing carpets for Audi A2; the Ford MONDEO;

Mercedes SLK; OPEL ASTRA, EPSILON, SAPHIRA; Porsche 982,996; Volkswagen COLORADO, POLO, GOLF, PASSAT NEW

BEETLE Chrysler, Skoda, Seat, Peugeot, BMW, Volvo and many other automobile models

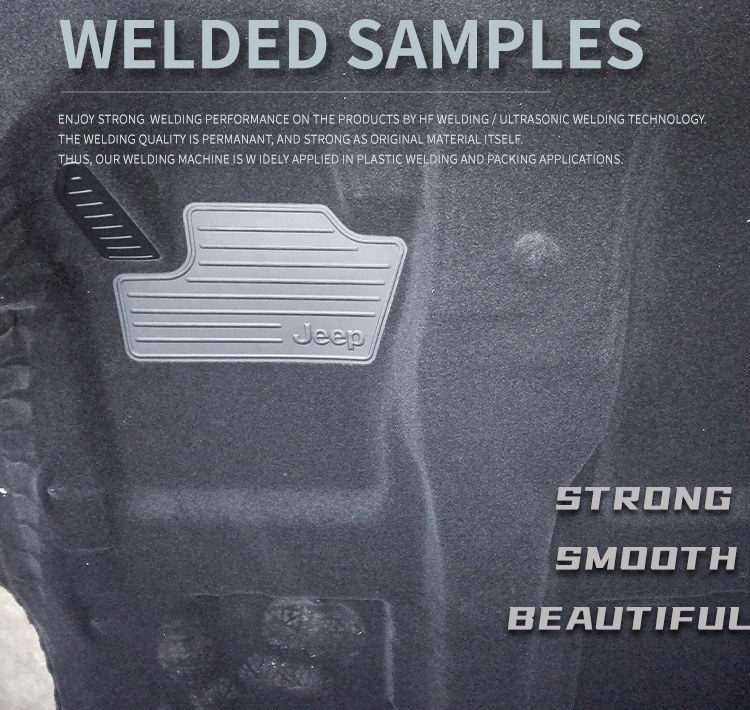

Apply for welding the heel-mat on the carpet

2. Suitable for LHD & RHD car.

3. Customized service offered.

4. Hydraulic Pressure from 2 ton -5 ton.

5. PLC programmed

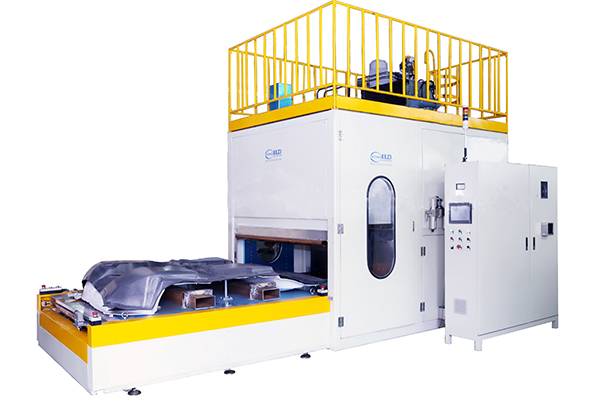

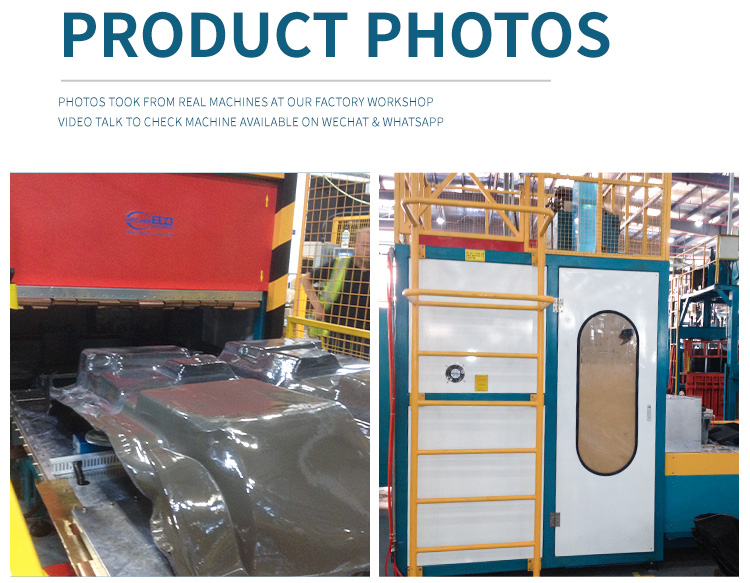

Carpet High Frequency Automotive Part Welding Machine

Product Introduction:

High Frequenc Welding Machine for Automobile Carpet

High Frequency Welding Machine for Automobile carpet which is suitable for PVC heelmat and automobile carpet .

Model | HR-15KW-2QT | HR-25KW-2QT |

HF Power | 15KW | 25KW |

HF Frequency | 27.12MHZ | 13.56MHZ |

Input Power: | 18KVA | 25KVA |

HF Generator | HIPOWER 15KW | HIPOWER 25KW |

Voltage | AC 380V 3Phases 50HZ / Customer request | |

Pneumatic Pressure | 0.1 - 0.8Mpa | |

Max. Pressure: | 5T Hydraulic Pressure | |

Max. Electrodes Gap : | 250mm / On Request | |

Control Method | PLC+HMI Touch screen | |

Upper Electrode: | 400*500mm or up to product size | |

Lower Work Platen: | 400*500mm or up to product size | |

Output Time | 0.01 - 30S Adjustable | |

Parameter Setting | HF Power+Time Adjusting+Pressure Adjusting | |

Welding Depth Setting | HF Power+Time Adjusting+Pressure Adjusting | |

Balance Setting | Upper Electrode Balance + Balance Screws Adjusting | |

Optional Function | Auto Tuning System | |

Standard | CE Certificate | |

3. Machine Features:

Auto Tuning System of HF welding power

Mold auto identification function.

Parameter Settings auto save

Various Welding Direction

European Parts Inside

Welding pressure: 5T hydraulic

System Auto diagnosis

Qualified RF Radiation Level

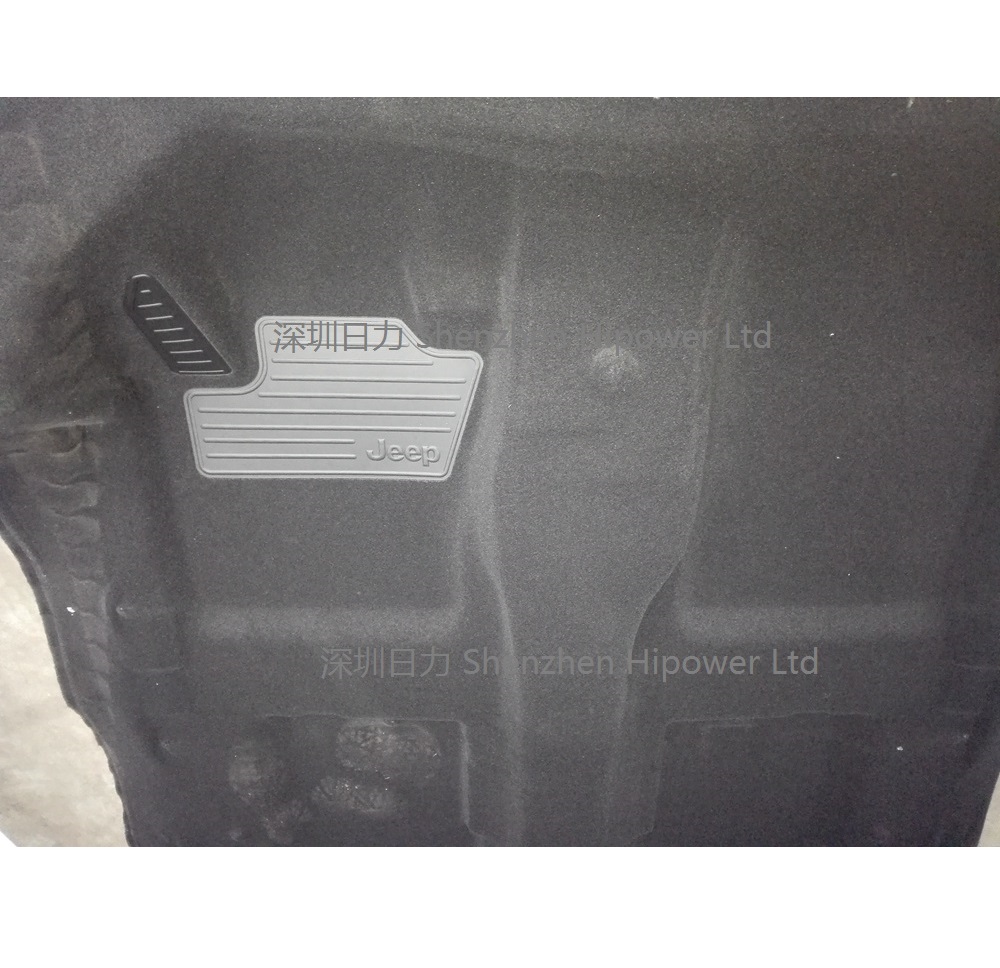

4. Application:

Automatic Car Carpet Welding Machine is specially designed for producing carpets for Audi A2; the Ford MONDEO;

Mercedes SLK; OPEL ASTRA, EPSILON, SAPHIRA; Porsche 982,996; Volkswagen COLORADO, POLO, GOLF, PASSAT NEW

BEETLE Chrysler, Skoda, Seat, Peugeot, BMW, Volvo and many other automobile models

Apply for welding the heel-mat on the carpet

2. Suitable for LHD & RHD car.

3. Customized service offered.

4. Hydraulic Pressure from 2 ton -5 ton.

5. PLC programmed

Carpet High Frequency Automotive Part Welding Machine

Carpet High Frequency Automotive Part Welding Machine

Carpet High Frequency Automotive Part Welding Machine