| Availability: | |

|---|---|

| Quantity: | |

HR-12KW-F1 750mm

HIPOWER

Product Introduction:

Banner High Frequency PVC Welding Machine is applied to weld pvc products. Any pvc bases procuts like canvas, tarpaulin, textile can be welded by the machine.

Banner PVC Welding Machine

1. Spark suppressor: When sparks, the special electronic circuit works and cuts off the high frequency to suppress spark automatically and minimize the damage of electrodes and materials. Also. The warning lights works.

2. Prevention for radio interference device: Equipped with frequency stabilizer and high-frequency magnetic leakage suppressor. This device eliminates the leakage of radio waves to interfere other electronic devices such as TV, radios, etc..

3. Safety devices: When the current exceeds the limit value, the overload current relay works to protect oscillator and rectifier automatically. Frequency deviation caused by the improper operation is also prevented.

4. Easily adjustable device: Output power can be adjusted according to electrode size and material thickness. Other control devices and special electronic circuits can reduce required welding time and improve the machine's productivity.

Since 2000, Hipower concentrates on highest quality, on-time delivery, professional technology

support, customer-oriented service and competitive price.

1. Customer's site installation, training & maintenance available

2. (Time zone difference) 1-12 hours Online service by Email, Fax, Video Online for basic setup and repairs

3. Service of 12 months warranty for machine, life-long tech. support

4. Examining mold drawings on your behalf to confirm optimum structure size meeting high frequency process;

5. Providing assistance in manufacturing and modifying tools;

Model | HR-10KW-R | HR-12KW-R | HR-15KW-R |

HF Power | 10KW | 12KW | 15KW |

HF Frequency | 27.12MHZ | ||

Voltage | AC 380V 3Phases 50HZ | ||

Pneumatic Pressure | 0.1 - 0.8Mpa | ||

Input Power: | 25KVA | ||

Max. Pressure: | 800 to 1000 KGS (Cylinder D160mm) | ||

Max. Electrodes Gap : | 150MM | ||

Electrode Moving Journey: | 150MM | ||

Upper Electrode: | 50*50*900mm (Maximum Mold Length:1000mm) | ||

Lower Work Platen: | 400*1100mm | ||

Output Time | 0.01 - 30S Adjustable | ||

Laser Light | included | ||

Rollers on work platen | included | ||

Rollers at bottom of Space | included | ||

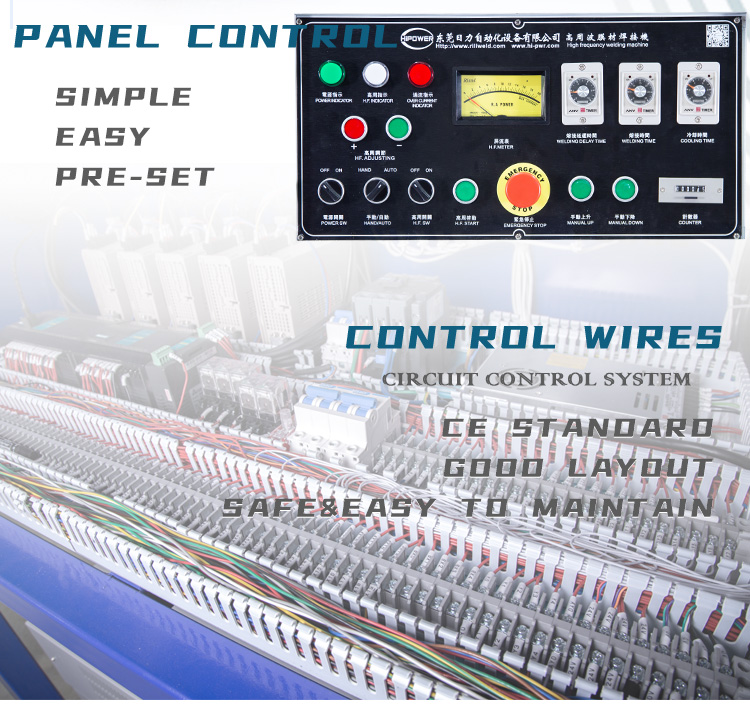

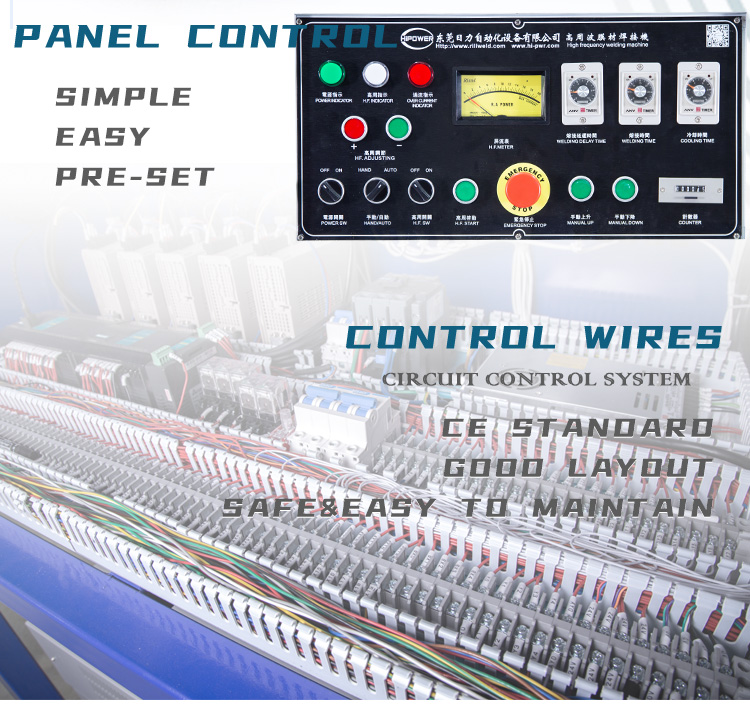

Control Method | Control Panel Type( PLC+HMI Touch screen on extra cost) | ||

Space behind | 1150mm | ||

HF Generator | HIPOWER 10KW | HIPOWER 12KW | HIPOWER 15KW |

Parameter Setting | HF Power+Time Adjusting+Pressure Adjusting | ||

Welding Depth Setting | HF Power+Time Adjusting+Pressure Adjusting | ||

Balance Setting | Upper Electrode Balance + Balance Screws Adjusting | ||

Optional Function | Auto Tuning System on Extra cost | ||

Standard | CE Certificate | ||

Packing Information | L2050*W1250*H1950 mm; G.W.: 980KGS; | ||

Characteristics:

Enjoy big free space behind electrode;

featuered with deep and wide material-feeding tank

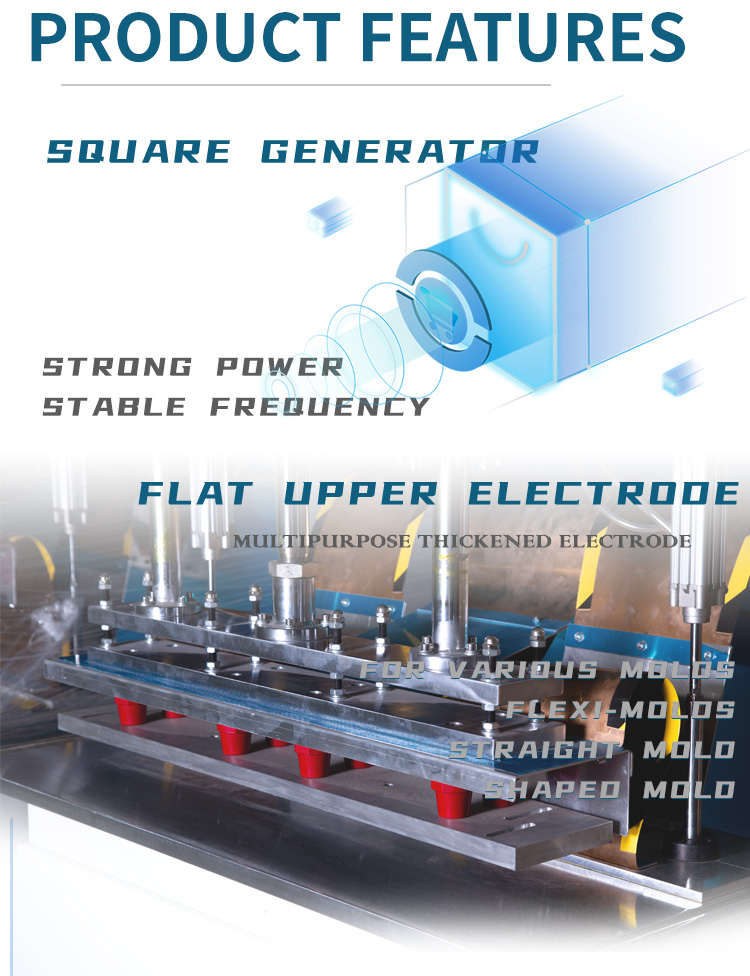

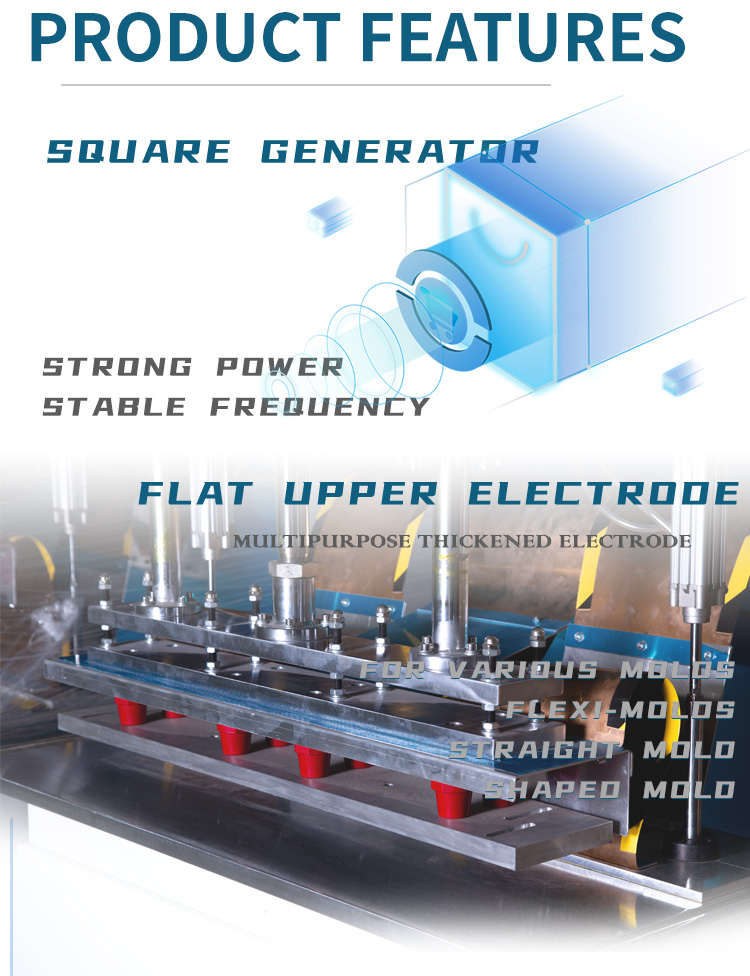

1. European Designed Generator: Strong, Stable and low HF radiation Level

2. With big free space behind welding bar: 1150mm (from middle of welding bar to the back)

3. Pedal operated, to free your hands

4. Laser light to help keep the position of product

5. Original New air cooling for electron tube

6. Special HF Radiation treatment

7. European oriented grounding plate behind welding bar

8. Easy to install straight / curved mold

9. Quality wheels, easy to move around freely

10. CE certificate, be able to exported to many countries

4. Application:

1. Large format technical textiles,

2. Large Covers for trucks and boats

3. Membrane Curtains for trucks

4. Large Swimming pool covers 5. Temporary shelters

Product Introduction:

Banner High Frequency PVC Welding Machine is applied to weld pvc products. Any pvc bases procuts like canvas, tarpaulin, textile can be welded by the machine.

Banner PVC Welding Machine

1. Spark suppressor: When sparks, the special electronic circuit works and cuts off the high frequency to suppress spark automatically and minimize the damage of electrodes and materials. Also. The warning lights works.

2. Prevention for radio interference device: Equipped with frequency stabilizer and high-frequency magnetic leakage suppressor. This device eliminates the leakage of radio waves to interfere other electronic devices such as TV, radios, etc..

3. Safety devices: When the current exceeds the limit value, the overload current relay works to protect oscillator and rectifier automatically. Frequency deviation caused by the improper operation is also prevented.

4. Easily adjustable device: Output power can be adjusted according to electrode size and material thickness. Other control devices and special electronic circuits can reduce required welding time and improve the machine's productivity.

Since 2000, Hipower concentrates on highest quality, on-time delivery, professional technology

support, customer-oriented service and competitive price.

1. Customer's site installation, training & maintenance available

2. (Time zone difference) 1-12 hours Online service by Email, Fax, Video Online for basic setup and repairs

3. Service of 12 months warranty for machine, life-long tech. support

4. Examining mold drawings on your behalf to confirm optimum structure size meeting high frequency process;

5. Providing assistance in manufacturing and modifying tools;

Model | HR-10KW-R | HR-12KW-R | HR-15KW-R |

HF Power | 10KW | 12KW | 15KW |

HF Frequency | 27.12MHZ | ||

Voltage | AC 380V 3Phases 50HZ | ||

Pneumatic Pressure | 0.1 - 0.8Mpa | ||

Input Power: | 25KVA | ||

Max. Pressure: | 800 to 1000 KGS (Cylinder D160mm) | ||

Max. Electrodes Gap : | 150MM | ||

Electrode Moving Journey: | 150MM | ||

Upper Electrode: | 50*50*900mm (Maximum Mold Length:1000mm) | ||

Lower Work Platen: | 400*1100mm | ||

Output Time | 0.01 - 30S Adjustable | ||

Laser Light | included | ||

Rollers on work platen | included | ||

Rollers at bottom of Space | included | ||

Control Method | Control Panel Type( PLC+HMI Touch screen on extra cost) | ||

Space behind | 1150mm | ||

HF Generator | HIPOWER 10KW | HIPOWER 12KW | HIPOWER 15KW |

Parameter Setting | HF Power+Time Adjusting+Pressure Adjusting | ||

Welding Depth Setting | HF Power+Time Adjusting+Pressure Adjusting | ||

Balance Setting | Upper Electrode Balance + Balance Screws Adjusting | ||

Optional Function | Auto Tuning System on Extra cost | ||

Standard | CE Certificate | ||

Packing Information | L2050*W1250*H1950 mm; G.W.: 980KGS; | ||

Characteristics:

Enjoy big free space behind electrode;

featuered with deep and wide material-feeding tank

1. European Designed Generator: Strong, Stable and low HF radiation Level

2. With big free space behind welding bar: 1150mm (from middle of welding bar to the back)

3. Pedal operated, to free your hands

4. Laser light to help keep the position of product

5. Original New air cooling for electron tube

6. Special HF Radiation treatment

7. European oriented grounding plate behind welding bar

8. Easy to install straight / curved mold

9. Quality wheels, easy to move around freely

10. CE certificate, be able to exported to many countries

4. Application:

1. Large format technical textiles,

2. Large Covers for trucks and boats

3. Membrane Curtains for trucks

4. Large Swimming pool covers 5. Temporary shelters