| Availability: | |

|---|---|

| Quantity: | |

HY-2615Y-4AC

HIPOWER

Product Introduction:

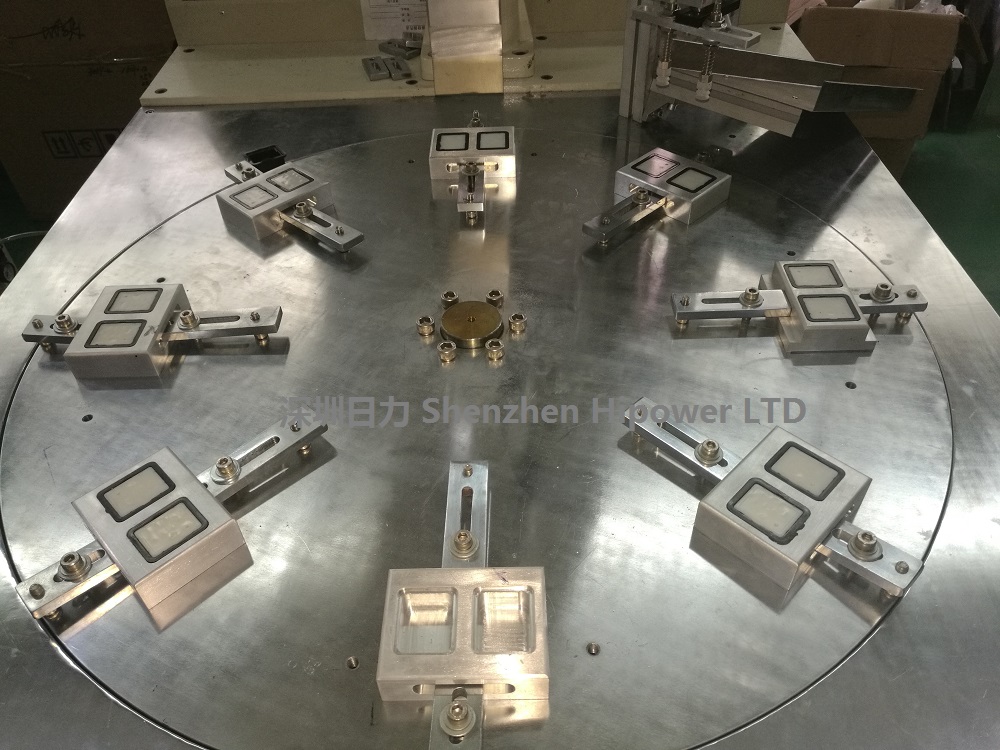

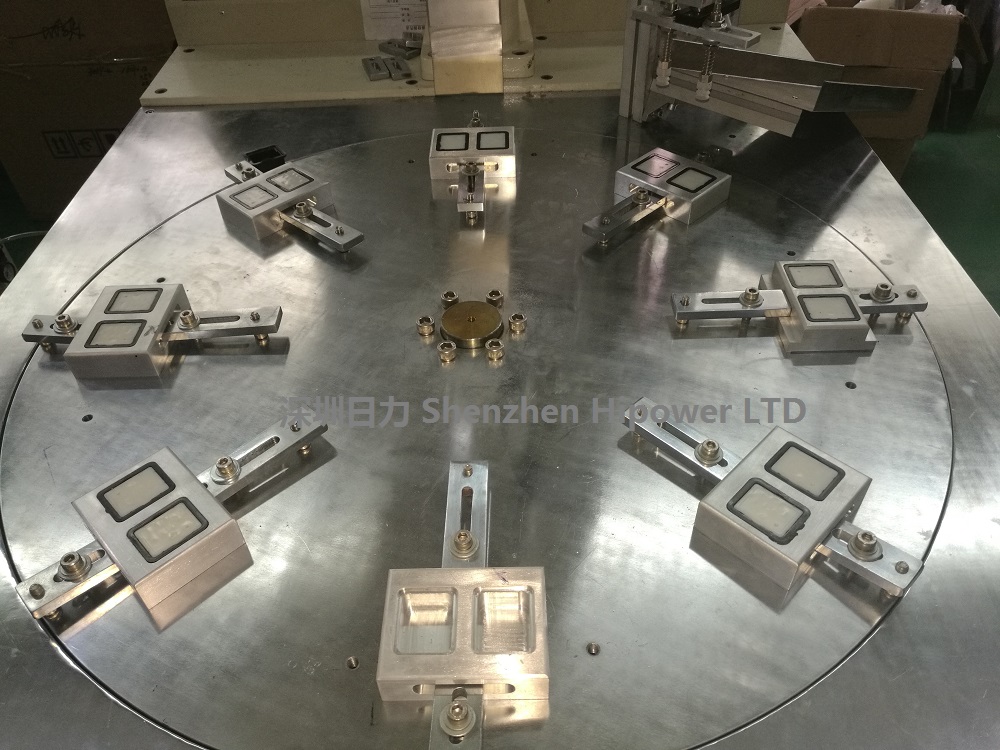

Automatic Plastic Ultrasonic Welding Machine

Model | HC-2615D-4AC |

Control Type | Touch Screen |

Ultrasonic Output Power | 1500W |

Ultrasonic Frequency | 20KHZ |

Welding Time | 0.01 - 9.99S |

Voltage | Single Phase: 220V 50HZ |

Air Pressure | 0.1 - 0.7Mpa |

Welding Surface Area | 150mm |

Horn Moving Journey | 75mm |

Horn Cooling | Air Cooling |

Ultrasonic Generator | Made in China |

Welding Setting | Power adjusting+Amplitude adjusting+time adjusting |

Welding Depth | Upper Electrode Limit+ Balance Screws Adjusting |

Welding Balance | Upper Horn Balance + Balance Screws Adjusting |

Control Type | Touch Screen |

Horn Gap Adjusting | Slider + Hard Track |

Generator Dimension(mm) | L480 x W 580 x H 180 mm |

Overall Dimension(mm) | L700 x W 600 x H 1000 mm |

Gross Weight | 85KGS |

Certificate | CE Certificate |

Ultrasonic welding, for thermoplastic injection moulded components, is a process that uses mechanical vibrations above the audible range. The vibrations, produced by a welding sonotrode or horn, as it is generally known, are used to soften or melt the thermoplastic material at the joint line. The components to be joined are held together under pressure and subjected to vibrations, usually at a frequency of 20 or 40kHz.

IC circuit precision control, automatic overload protection system

Adopting digital switch, 1/100 precision re-set control

Adjustable horizontal level, easy control welding horn

High Q value transducer, optimized output

Have resonant frequency when the load, unload, without adjustment for the frequency of welding horn

Square column and column airframe structure is optional, the straight line guide bearing, the precise matching device

Using the turbine rotation to adjust the machine movement, which is better than normal

Adopting Japan HuangPai brand alloy steel to keep frequency strong and stable

Celebrate itself durability for adopting USA aviation standard 7075¡¢6064 Aluminum alloy

The electronic components are imported from Italy, Japan, American, South Korean, Taiwan directly, guarantee the quality of our machine.

All in one high capacity machine, applied for high precision of welding workpiece.

Automatic protective device, which is optional.

High-power machine, which is applied for Large workpiece.

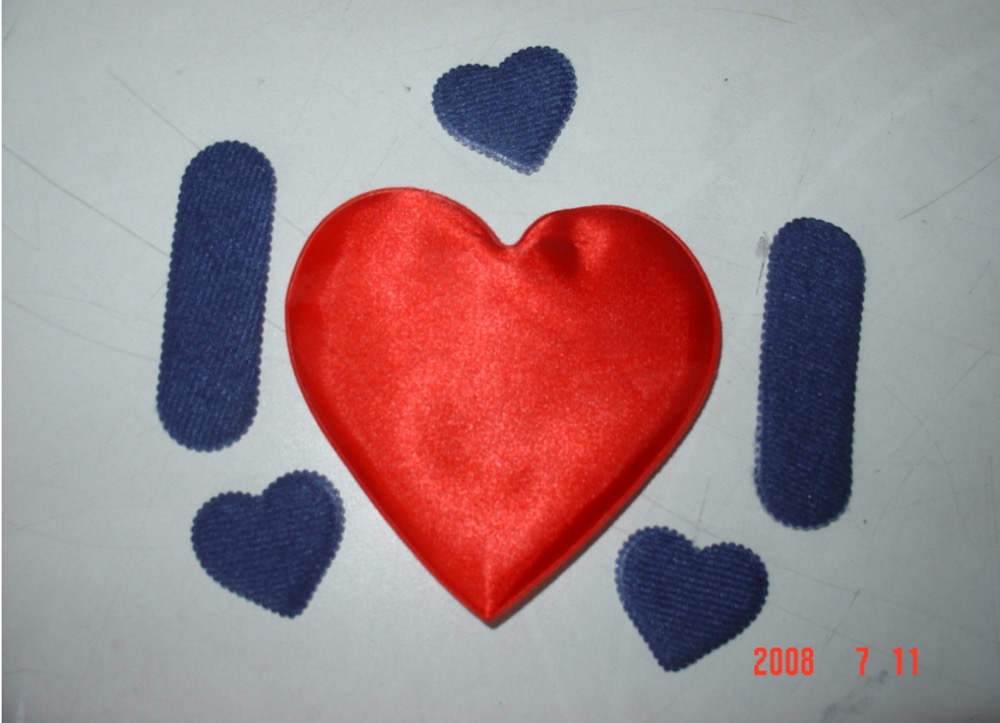

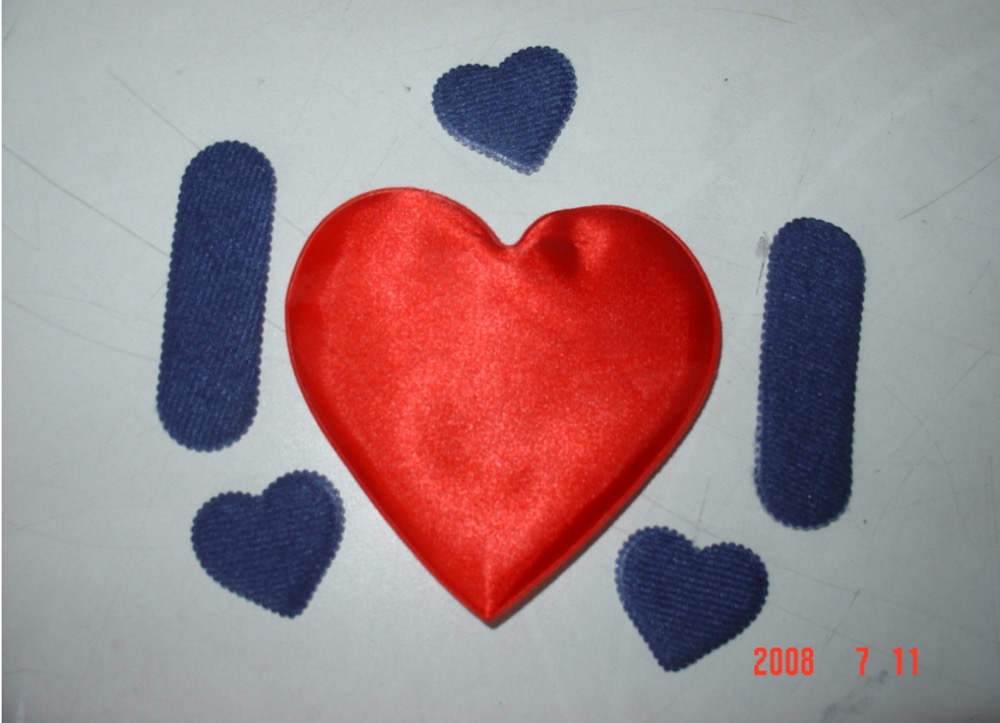

Applied : Widely used in aviation, boats, cars, electrical appliance, package, toys, electric, medical, auto parts, fishing and textiles etc.

Since 2000, Hipower concentrates on highest quality, on-time delivery, professional technology

support, customer-oriented service and competitive price.

1. Customer's site installation, training & maintenance available

2. (Time zone difference) 1-12 hours Online service by Email, Fax, Video Online for basic setup and repairs

3. Service of 12 months warranty for machine, life-long tech. support

4. Examining mold drawings on your behalf to confirm optimum structure size meeting high frequency process;

5. Providing assistance in manufacturing and modifying tools;

New Type TPU Ultrasonic Welding Machine

Chinese manufacturer in Dongguan, China. With 22 years experience.

Product Introduction:

Automatic Plastic Ultrasonic Welding Machine

Model | HC-2615D-4AC |

Control Type | Touch Screen |

Ultrasonic Output Power | 1500W |

Ultrasonic Frequency | 20KHZ |

Welding Time | 0.01 - 9.99S |

Voltage | Single Phase: 220V 50HZ |

Air Pressure | 0.1 - 0.7Mpa |

Welding Surface Area | 150mm |

Horn Moving Journey | 75mm |

Horn Cooling | Air Cooling |

Ultrasonic Generator | Made in China |

Welding Setting | Power adjusting+Amplitude adjusting+time adjusting |

Welding Depth | Upper Electrode Limit+ Balance Screws Adjusting |

Welding Balance | Upper Horn Balance + Balance Screws Adjusting |

Control Type | Touch Screen |

Horn Gap Adjusting | Slider + Hard Track |

Generator Dimension(mm) | L480 x W 580 x H 180 mm |

Overall Dimension(mm) | L700 x W 600 x H 1000 mm |

Gross Weight | 85KGS |

Certificate | CE Certificate |

Ultrasonic welding, for thermoplastic injection moulded components, is a process that uses mechanical vibrations above the audible range. The vibrations, produced by a welding sonotrode or horn, as it is generally known, are used to soften or melt the thermoplastic material at the joint line. The components to be joined are held together under pressure and subjected to vibrations, usually at a frequency of 20 or 40kHz.

IC circuit precision control, automatic overload protection system

Adopting digital switch, 1/100 precision re-set control

Adjustable horizontal level, easy control welding horn

High Q value transducer, optimized output

Have resonant frequency when the load, unload, without adjustment for the frequency of welding horn

Square column and column airframe structure is optional, the straight line guide bearing, the precise matching device

Using the turbine rotation to adjust the machine movement, which is better than normal

Adopting Japan HuangPai brand alloy steel to keep frequency strong and stable

Celebrate itself durability for adopting USA aviation standard 7075¡¢6064 Aluminum alloy

The electronic components are imported from Italy, Japan, American, South Korean, Taiwan directly, guarantee the quality of our machine.

All in one high capacity machine, applied for high precision of welding workpiece.

Automatic protective device, which is optional.

High-power machine, which is applied for Large workpiece.

Applied : Widely used in aviation, boats, cars, electrical appliance, package, toys, electric, medical, auto parts, fishing and textiles etc.

Since 2000, Hipower concentrates on highest quality, on-time delivery, professional technology

support, customer-oriented service and competitive price.

1. Customer's site installation, training & maintenance available

2. (Time zone difference) 1-12 hours Online service by Email, Fax, Video Online for basic setup and repairs

3. Service of 12 months warranty for machine, life-long tech. support

4. Examining mold drawings on your behalf to confirm optimum structure size meeting high frequency process;

5. Providing assistance in manufacturing and modifying tools;

New Type TPU Ultrasonic Welding Machine

Chinese manufacturer in Dongguan, China. With 22 years experience.