| Availability: | |

|---|---|

| Quantity: | |

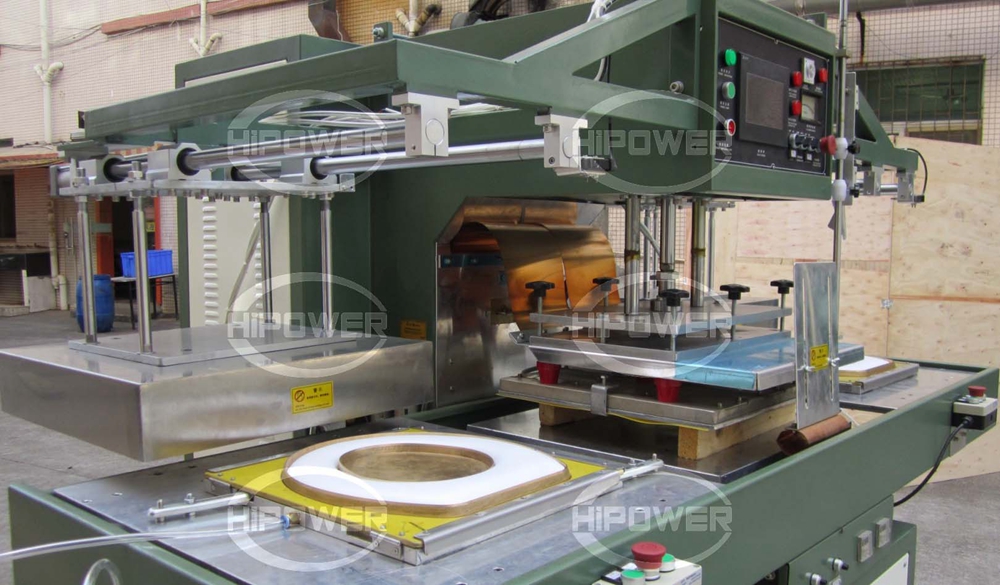

HC-80000AT

HIPOWER

Product Introduction:

How to make Cushion Toilet Seats Products by High Frequency Welding Machine ?

Hipower is able to produce it automatically.

Process 1: The operator put lower layer pvc and fix on the lower mold

Process 2: The machine start heat pvc to soft, and do vaccum forming

Process 3: The operator put sponge + top layer pvc , Sliding table come in working station automatically

Process 4: The machine do HF welding and cutting

Process 5: Sliding table comes out automatically, the operator pick up finished product

Repeat above workflow again and again.

Model | HR-5000AT | HR-8000AT | HR-12KWAT | HR-15KWAT |

HF Power | 5KW | 8KW | 12KW | 15KW |

HF Frequency | 27.12MHZ | |||

Voltage | AC 380V 3Phases 50HZ / Customer request | |||

Pneumatic Pressure | 0.1 - 0.8Mpa | |||

Input Power: | 7KVA | 15KVA | 20KVA | 25KVA |

Max. Pressure: | 800 to 1000 KGS | |||

Max. Electrodes Gap : | 150MM | |||

Electrode Gap: | 175MM | |||

Upper Electrode: | 200*350mm | 400*600mm | 400*600mm | 500*700mm |

Lower Work Platen: | 200*350mm | 400*600mm | 400*600mm | 500*700mm |

Output Time | 0.01 - 30S Adjustable | |||

Control Method | Control Panel Type( PLC+HMI Touch screen on extra cost) | |||

HF Generator | HIPOWER 5KW | HIPOWER 8KW | HIPOWER 12KW | HIPOWER 15KW |

Parameter Setting | HF Power+Time Adjusting+Pressure Adjusting | |||

Welding Depth Setting | HF Power+Time Adjusting+Pressure Adjusting | |||

Balance Setting | Upper Electrode Balance + Balance Screws Adjusting | |||

Optional Function | Auto Tuning System on Extra cost | |||

Standard | CE Certificate | |||

Packing Information | L2050*W1050*H1950 mm; G.W.: 600KGS; | L2150*W1050*H1950 mm; G.W.: 750KGS; | L2150*W1050*H1950 mm; G.W.: 800KGS; | L2200*W1050*H1950 mm; G.W.: 800KGS; |

1. European Designed Generator: Strong, Stable and low HF radiation Level

2. Three sides HF grounding design, less HF radiation around the machine

3. Auto sliding table machine, to share one generator.

4. Workers’ working loading is less heavy with auto sliding table

5. Original New air cooling for electron tube

6. Special HF Radiation treatment

7. Quality wheels, easy to move around freely

8. CE certificate, be able to exported to many countries

Auto Sliding Table HF PVC Toilet Cushion Seat Cover Welding Machine

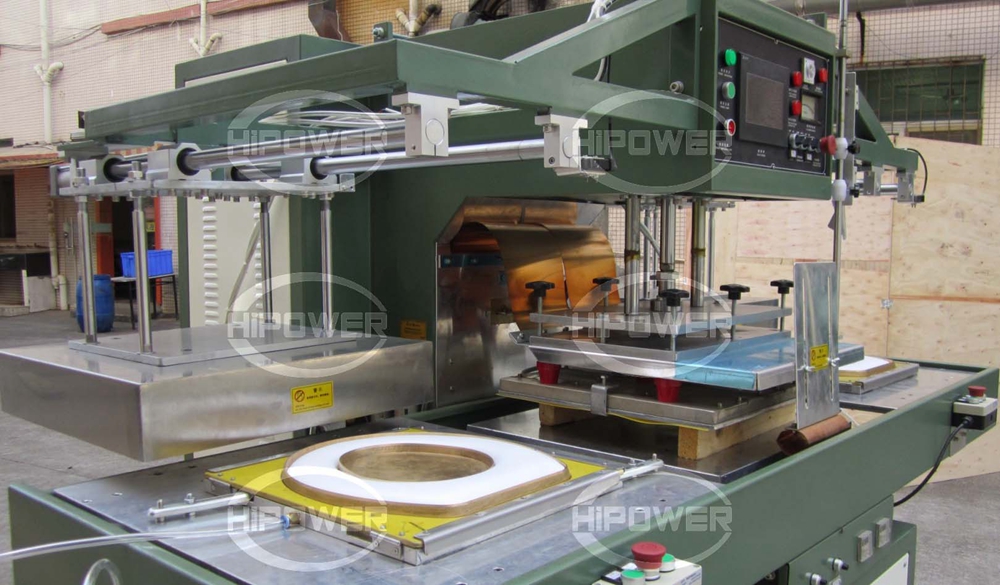

Product Introduction:

How to make Cushion Toilet Seats Products by High Frequency Welding Machine ?

Hipower is able to produce it automatically.

Process 1: The operator put lower layer pvc and fix on the lower mold

Process 2: The machine start heat pvc to soft, and do vaccum forming

Process 3: The operator put sponge + top layer pvc , Sliding table come in working station automatically

Process 4: The machine do HF welding and cutting

Process 5: Sliding table comes out automatically, the operator pick up finished product

Repeat above workflow again and again.

Model | HR-5000AT | HR-8000AT | HR-12KWAT | HR-15KWAT |

HF Power | 5KW | 8KW | 12KW | 15KW |

HF Frequency | 27.12MHZ | |||

Voltage | AC 380V 3Phases 50HZ / Customer request | |||

Pneumatic Pressure | 0.1 - 0.8Mpa | |||

Input Power: | 7KVA | 15KVA | 20KVA | 25KVA |

Max. Pressure: | 800 to 1000 KGS | |||

Max. Electrodes Gap : | 150MM | |||

Electrode Gap: | 175MM | |||

Upper Electrode: | 200*350mm | 400*600mm | 400*600mm | 500*700mm |

Lower Work Platen: | 200*350mm | 400*600mm | 400*600mm | 500*700mm |

Output Time | 0.01 - 30S Adjustable | |||

Control Method | Control Panel Type( PLC+HMI Touch screen on extra cost) | |||

HF Generator | HIPOWER 5KW | HIPOWER 8KW | HIPOWER 12KW | HIPOWER 15KW |

Parameter Setting | HF Power+Time Adjusting+Pressure Adjusting | |||

Welding Depth Setting | HF Power+Time Adjusting+Pressure Adjusting | |||

Balance Setting | Upper Electrode Balance + Balance Screws Adjusting | |||

Optional Function | Auto Tuning System on Extra cost | |||

Standard | CE Certificate | |||

Packing Information | L2050*W1050*H1950 mm; G.W.: 600KGS; | L2150*W1050*H1950 mm; G.W.: 750KGS; | L2150*W1050*H1950 mm; G.W.: 800KGS; | L2200*W1050*H1950 mm; G.W.: 800KGS; |

1. European Designed Generator: Strong, Stable and low HF radiation Level

2. Three sides HF grounding design, less HF radiation around the machine

3. Auto sliding table machine, to share one generator.

4. Workers’ working loading is less heavy with auto sliding table

5. Original New air cooling for electron tube

6. Special HF Radiation treatment

7. Quality wheels, easy to move around freely

8. CE certificate, be able to exported to many countries

Auto Sliding Table HF PVC Toilet Cushion Seat Cover Welding Machine